Introduction to Spezialbohrgetriebe

The term Spezialbohrgetriebe, which translates from German as “special drilling gearbox,” refers to highly engineered gear systems designed to handle drilling applications that go far beyond standard requirements. These gearboxes are not ordinary transmission units; they are built to withstand extreme loads, high torque demands, unusual angles, and continuous operation in both industrial and construction environments.

Unlike conventional gear drives, which are designed for general power transmission, spezialbohrgetriebe are customized to adapt to unique operational conditions. Industries such as tunnel boring, mining, oil and gas, shipbuilding, and large-scale infrastructure projects rely heavily on these gearboxes for precise, safe, and efficient performance. Over the years, manufacturers have evolved their designs to handle growing demands for higher productivity, longer durability, and more environmentally friendly solutions.

Historical Development of Drilling Gearboxes

The concept of a drilling gearbox can be traced back to early industrial revolutions when mining and construction required heavy-duty machinery to break through rock formations and underground surfaces. Early drilling machines used simplistic gear systems, which often failed under high loads and heat. As engineering advanced, German mechanical specialists began experimenting with hardened steel, lubrication systems, and modular gearbox construction to create more durable solutions.

The spezialbohrgetriebe emerged during the 20th century as industries demanded drilling systems capable of handling precise alignment, controlled torque, and customized configurations. Modern innovations now integrate digital monitoring, computer-aided design (CAD) optimization, and eco-friendly lubrication technologies to create gearboxes that perform under extreme environmental conditions.

Design and Construction of Spezialbohrgetriebe

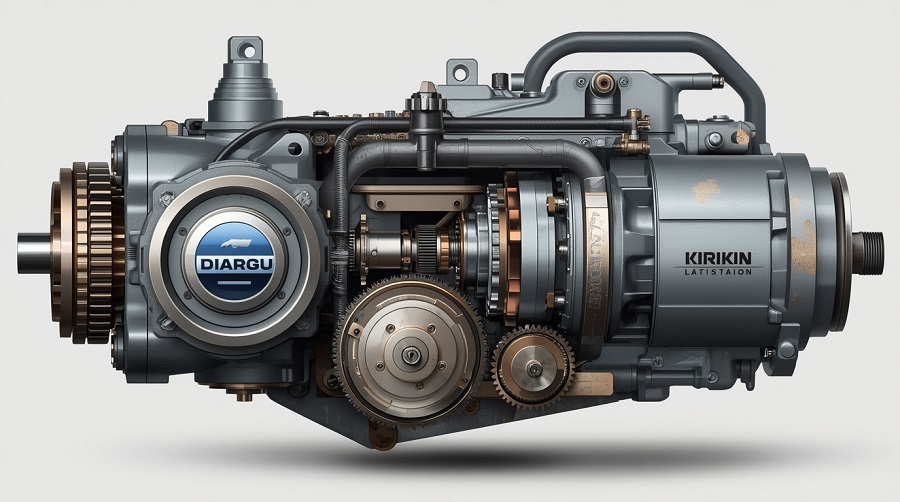

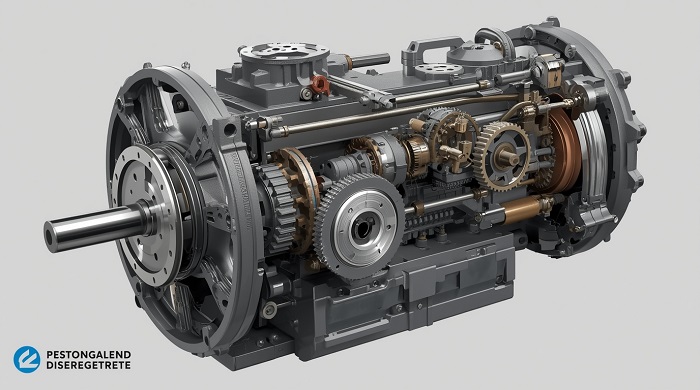

The design of a spezialbohrgetriebe is centered on performance, durability, and adaptability. At its core, the gearbox contains hardened gear wheels made from high-grade alloy steel, treated with advanced surface-hardening processes to increase wear resistance. The gears are typically helical or planetary in configuration, which ensures smooth power transmission and reduced vibration during drilling operations. The housing is robust, often made from cast iron or forged steel, designed to protect the gears from dust, water, and debris.

A vital part of the design is the lubrication system, which ensures continuous oil circulation to minimize friction and overheating. Some specialized gearboxes also include built-in cooling systems, pressure relief valves, and vibration dampeners to extend operational life. Engineers can customize gear ratios, torque output, and gear alignment depending on whether the gearbox is used in horizontal drilling, vertical boring, or angled shaft drilling.

Applications in Industrial Sectors

Spezialbohrgetriebe find application across multiple industrial domains where standard gearboxes would fail. In the mining industry, these gearboxes are crucial for rock drilling machines that must penetrate hard geological formations. In oil and gas, they drive drilling rigs that reach thousands of meters underground. Construction industries use them in tunnel boring machines (TBMs) for metro projects, highways, and underwater passages.

Shipbuilding industries employ them for precision drilling in hull and propeller shaft constructions. Renewable energy sectors also integrate spezialbohrgetriebe into wind turbine foundation drilling, where precise torque and depth control are essential. Because of their customization, each gearbox is designed according to the unique requirements of the project, ensuring both efficiency and long service life.

Importance of Torque and Power Transmission

One of the defining features of a spezialbohrgetriebe is its ability to handle massive torque while maintaining smooth power transmission. Unlike standard mechanical systems, which may struggle with sudden load changes, these gearboxes are engineered to distribute forces evenly across multiple gear stages. This prevents gear tooth failure, reduces vibration, and ensures consistent drilling performance even under fluctuating conditions. High torque is essential in deep drilling operations, where resistance increases with depth and material hardness. Power transmission efficiency is maximized through precision-engineered gear ratios, ensuring that energy from the motor is effectively converted into drilling motion without unnecessary loss.

Technological Innovations in Spezialbohrgetriebe

Modern spezialbohrgetriebe are far more advanced than their predecessors. Innovations include the integration of sensor-based monitoring systems that provide real-time data on temperature, vibration, torque, and lubrication levels. This allows predictive maintenance, reducing downtime and preventing catastrophic failures. Computer-aided engineering (CAE) tools enable manufacturers to simulate stress conditions before production, resulting in optimized designs that are lighter yet stronger.

Environmentally friendly lubricants reduce ecological impact, while compact modular designs make installation and transport easier. Some gearboxes now feature smart automation controls, allowing operators to adjust torque and speed dynamically depending on drilling conditions. These technological improvements make spezialbohrgetriebe not just mechanical components but intelligent systems that contribute to overall operational efficiency.

Customization and Adaptability

Every drilling project comes with unique challenges—different soil compositions, depth requirements, environmental restrictions, and load conditions. This is why spezialbohrgetriebe are often custom-built rather than standardized. Engineers collaborate with project managers to analyze requirements and develop gearboxes with specific gear ratios, casing materials, and safety features. For example, gearboxes used in arctic oil drilling are designed with heating systems to prevent lubrication freezing, while those in desert mining are equipped with dust-sealed housings.

Tunnel boring machines often require massive gearboxes with planetary gear arrangements capable of handling thousands of tons of thrust. The adaptability of spezialbohrgetriebe ensures that no matter the operational condition, there is a reliable gearbox solution available.

Maintenance and Longevity

A spezialbohrgetriebe is a long-term investment, and its longevity depends heavily on proper maintenance. Regular oil checks, temperature monitoring, and vibration analysis are essential to keep the gearbox in optimal condition. Manufacturers often provide maintenance schedules that include gear inspections, seal replacements, and lubrication changes. Predictive maintenance technologies, aided by sensors and AI analytics, can now forecast potential failures before they occur, reducing costly downtime. With proper care, a spezialbohrgetriebe can last for decades, providing reliable service in even the harshest conditions.

Economic Impact and Cost Efficiency

Although spezialbohrgetriebe are more expensive than standard gearboxes, they provide significant cost benefits over time. Their durability reduces the need for frequent replacements, and their efficiency lowers energy consumption during drilling operations. In large-scale projects, downtime caused by gearbox failure can cost millions of dollars, making reliability a key factor in overall project economics. Additionally, advancements in manufacturing have made custom-built gearboxes more affordable than ever, allowing smaller companies to benefit from specialized drilling gear technology. The long-term cost efficiency of spezialbohrgetriebe makes them indispensable in industries where precision, safety, and reliability are non-negotiable.

Environmental Considerations

As industries move toward sustainability, spezialbohrgetriebe manufacturers are focusing on eco-friendly designs. Gearboxes now use biodegradable lubricants, energy-efficient gear designs, and recyclable materials for housing. Some companies are experimenting with hybrid systems that integrate electric drives with mechanical gear reduction, lowering carbon emissions in drilling operations. Noise reduction technologies are also being implemented to minimize environmental disturbances in urban drilling projects. These efforts reflect a growing awareness that industrial efficiency must go hand in hand with environmental responsibility.

Future Trends in Spezialbohrgetriebe

Looking ahead, the future of spezialbohrgetriebe will likely include even more digital integration, with artificial intelligence playing a significant role in performance optimization. Predictive maintenance will evolve into self-correcting systems, where the gearbox can automatically adjust lubrication or torque based on real-time conditions. Lightweight materials such as carbon composites may replace traditional steel housings, reducing energy consumption. As renewable energy projects expand, spezialbohrgetriebe will find new applications in geothermal drilling and offshore wind turbine construction. The integration of robotics and automation will also increase, with gearboxes becoming more intelligent and connected to broader industrial networks.

Conclusion

The spezialbohrgetriebe is far more than a gearbox it is a critical enabler of modern industry. From mining to renewable energy, these specialized drilling gear systems ensure precision, safety, and efficiency under the toughest conditions. Their adaptability, technological innovation, and durability make them a cornerstone of heavy industry. As engineering advances and sustainability becomes a global priority, spezialbohrgetriebe will continue to evolve, offering smarter, greener, and more powerful solutions for the challenges of tomorrow.

FAQs about Spezialbohrgetriebe

What is a spezialbohrgetriebe used for?

A spezialbohrgetriebe is a specialized gearbox used in drilling applications such as mining, tunnel boring, oil and gas drilling, and construction.

How is it different from a standard gearbox?

Unlike standard gearboxes, spezialbohrgetriebe are custom-built to handle high torque, extreme loads, and specific drilling conditions.

What industries commonly use these gearboxes?

They are widely used in mining, oil and gas, tunnel construction, shipbuilding, and renewable energy projects.

How long can a spezialbohrgetriebe last?

With proper maintenance, these gearboxes can last decades, depending on usage and environmental conditions.

Are spezialbohrgetriebe environmentally friendly?

Yes, modern versions use eco-friendly lubricants, energy-efficient designs, and recyclable materials to reduce environmental impact.