In an era where DIY car maintenance is booming—fueled by skyrocketing repair costs and the rise of electric vehicles demanding precise undercarriage access—a reliable trolley jack isn’t just a tool; it’s a lifeline. Whether you’re swapping winter tyres in your driveway or fine-tuning brakes in a home garage, the humble trolley jack transforms heavy lifting into a straightforward task.

What Is a Trolley Jack?

A trolley jack is also known as a floor jack or hydraulic trolley jack. It is a wheeled, portable lifting device designed to hoist vehicles for maintenance. Pump the handle, and hydraulic fluid pressurises a piston to raise the saddle up to 20 inches or more, providing access to tyres, suspension, or exhaust systems. Unlike clunky scissor jacks that come stock with cars, trolley jacks roll effortlessly under the vehicle, making them ideal for quick jobs like tyre rotations or oil changes.

Key Specs of Trolly Jack

Capacity: Typically 1.5 to 5 tons (3,000–10,000 lbs)

Lift Range: Minimum height (e.g., 3–5 inches for low-profile models) to maximum (12–21 inches)

Weight: 20–60 lbs, with aluminium models lighter for portability.

Born from early 20th-century garage innovations, trolley jacks evolved post-WWII with hydraulic tech, becoming staples in professional shops by the 1970s.

How Does a Trolley Jack Work?

Trolley jack’s principle is that pressure applied to a confined fluid transmits equally in all directions.

- Positioning: Roll the jack under the vehicle’s designated lift point.

- Pumping: Insert the handle into the pump linkage and raise/lower it rhythmically. Each stroke compresses hydraulic oil into the cylinder, extending the piston and lifting the saddle.

- Locking and Release: A safety valve locks the piston at height. To lower, open the release valve slowly via a side screw.

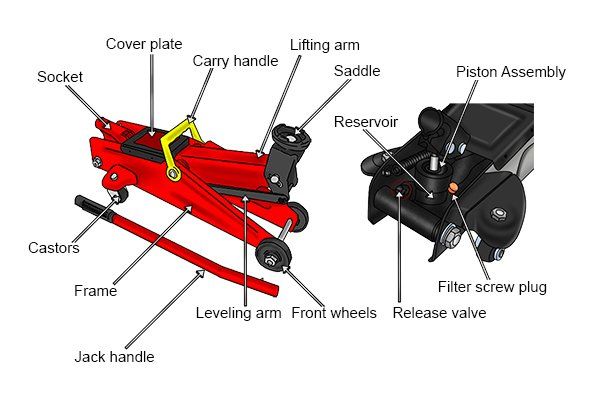

Components of Trolley Jack

The key components of a Trolley jack are:

- Chassis & Casters: Base with wheels for mobility

- Hydraulic Cylinder: Piston that extends to lift

- Saddle/Pad: Contacts the vehicle frame and uses adapters for unibody cars to avoid denting.

- Handle & Pump: Leverages force for pressure

- Release Valve: Controls descent and turns counterclockwise slowly.

Trolley Jack vs. Floor Jack

In most contexts, “trolley jack” and “floor jack” are interchangeable terms for the same beast. However, trolley jacks often imply compact, portable designs for home use, while floor jacks lean toward heavier-duty shop models with broader bases.

Trolley Jack Versus Other Jacks

Scissor Jack: Lighter (10–15 lbs) but slower and unstable; best for emergencies only.

Bottle Jack: Compact and cheap ($20–50) but tippy on uneven ground; great as a spare.

Transmission Jack: Specialised for engines; not a generalist like trolleys.

Top Trolley Jacks for 2025

Based on Trolley Jack’s price, sales data, user reviews, and lab tests, here’s a curated selection:

| Model | Capacity | Lift Range | Weight | Price (USD) | Standout Feature | Best For |

| Husky 2.5T Low Profile | 2.5 tons | 3.5–18 in | 42 lbs | $119 | Dual-pump for 40% faster lifts | Everyday DIYers; value king |

| BIG RED T820014S Torin | 2 tons | 5–13 in | 55 lbs | $85 | Steel build with blow-molded case | Budget garages; heavy-duty reliability |

| Sealey Premier 3T | 3 tons | 3.1–19.7 in | 62 lbs | $220 | Low-profile with overload valve | Pros; ultra-stable for EVs |

| Pittsburgh Racing (Harbor Freight) | 2 tons | 5.25–12 in | 30 lbs | $60 | Compact aluminum; trunk-friendly | Roadside emergencies; portable champ |

| ROGTZ Electric 5T | 5 tons | 4–20 in | 68 lbs | $250 | Battery-powered; no pumping | Heavy SUVs; fatigue-free ops |

How to Use a Trolley Jack Safely

Safety first—68% of garage accidents stem from improper jacking. Never work under a solo jack; always use stands. Follow this protocol:

- Park on level, hard ground. Engage the parking brake, chock the opposite wheels, and locate the lift points via manual.

- Check Jack for leaks, damage, or low fluid. Close the release valve clockwise.

- Roll under the lift point; ensure saddle aligns squarely.

- Pump handle 7–17 times until tyre clears ground (or higher for access). Snug stands under the frame.

- Lower slowly onto the stands; shake the vehicle to confirm stability. Crawl under only now.

- Reverse to lower—raise slightly to remove stands, then descend controlled.

Maintenance and Common Pitfalls

Trolley jacks last 10+ years with care.

Monthly Care: Check fluid (top up with hydraulic oil), lubricate linkages.

Annually Care: Bleed air by opening the valve over a bucket while pumping. Store dry, handle-up to avoid seal damage.

Watch for: Spongy lifts (air in the system), leaks (seal failure—warranty it), or uneven wheels (replace casters). Reddit users swear by Harbour Freight’s $60 models for light duty but warn against cheapos that leak after a season.

The Future of Lifting

As EVs proliferate (needing frequent battery bay access) and DIY surges 15% yearly, trolley jacks are evolving—think app-integrated load sensors and eco-fluids. They’re not just tools; they’re enablers of self-reliance, saving $500+ on shop fees annually.

Start with a 2-ton low-profile for under $100, add stands ($40/pair), and you’re set. Got a lift story or model rec? Share below—we’re all in this garage together.